| Issue |

Manufacturing Rev.

Volume 12, 2025

Advanced Manufacturing Research – Latest Developments

|

|

|---|---|---|

| Article Number | 18 | |

| Number of page(s) | 11 | |

| DOI | https://doi.org/10.1051/mfreview/2025010 | |

| Published online | 28 July 2025 | |

Original Article

Field-assisted sintering process and part characterisation of hafnium-free half Heusler thermoelectric material ZrNiSn

1

Centre for Precision Manufacturing, Design Manufacturing and Engineering Management Department, University of Strathclyde, G1 1XJ Glasgow, UK

2

Innova Nanojet Technologies Ltd, Glasgow, UK

3

James Watt School of Engineering, University of Glasgow, Glasgow, UK

4

MBN Nanomaterialia Spa, Vascon di Carbonera (TV), Italy

* e-mails: b.chen@strath.ac.uk; qin.yi@strath.ac.uk

Received:

18

October

2024

Accepted:

21

March

2025

Half-Heusler (HH) compounds have emerged as promising thermoelectric materials due to their excellent thermal stability, mechanical robustness, and environmentally friendly composition. In this study, we investigated a hafnium-free ZrNiSn-based half-Heusler compound, (Zr0.4Ti0.6)0.33Ni0.33(Sn0.98Sb0.02)0.33, synthesised through field-assisted sintering technology (FAST). This composition is developed to eliminate rare earth elements and costly hafnium while maintaining desirable thermoelectric properties. A systematic investigation of FAST processing parameters was conducted using factorial analysis, which revealed temperature as the most critical sintering parameter, followed by pressure, holding time, and heating rate. The FAST process has demonstrated excellent densification outcomes, achieving relative densities of up to 97.73%. Comprehensive characterisation of the optimised material showed a peak figure of merit (ZT) of 0.54 at 527 °C., with an average ZT value of 0.35 in the temperature range of 100–500 °C. This study demonstrates the potential of FAST in producing thermoelectric materials. It provides valuable insights into the relationship between processing parameters and material performance, contributing to developing sustainable and cost-effective materials for waste heat recovery applications.

Key words: Field-assisted sintering / thermoelectric / half heusler / ZrNiSn / figure of merit / seebeck coefficient

© B. Chen et al., Published by EDP Sciences 2025

This is an Open Access article distributed under the terms of the Creative Commons Attribution License (https://creativecommons.org/licenses/by/4.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

This is an Open Access article distributed under the terms of the Creative Commons Attribution License (https://creativecommons.org/licenses/by/4.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

1 Introduction

The global drive for sustainable energy solutions towards net-zero emissions has accelerated interest in innovative materials for energy harvesting applications. Among these, thermoelectric (TE) and piezoelectric (PE) ceramic materials have shown exceptional potential, given their capabilities to transform thermal and mechanical energies into electrical power [1,2]. However, despite their potential, industrialising and commercialising these materials face significant challenges. Conventional manufacturing methods suffer from prohibitively high energy consumption during prolonged processing cycles, with sintering operations often requiring ten or more hours at elevated temperatures. On the other hand, field-assisted sintering technology (FAST) has emerged as a promising approach to address these manufacturing challenges [3,4].

The FAST process is characterised by the simultaneous application of uniaxial pressure and pulsed direct current (DC) through a conductive die containing the powder material [5]. Depending on the chemical composition of the powder, the FAST process may require a protective atmosphere, such as a vacuum or inert gas environment, to avoid contamination and oxidisation during the high-temperature sintering process. This process generates Joule heating and potentially creates spark discharges between particles, though the precise mechanisms remain under investigation [6]. Compared to traditional sintering approaches, FAST achieves densification at reduced temperatures and shorter timeframes, utilising rapid heating rates (up to 1000 °C/min) and applied pressure (typically 20–100 MPa) [3]. Figure 1 below illustrates the fundamental concept of the FAST process [7].

Generally speaking, the FAST process involves several essential steps: (1) preparation and loading of TE/PE powders into a graphite die, (2) sintering chamber evacuation by vacuum or inert gas, (3) initial pressure application, (4) DC pulse-induced rapid heating, (5) maintain the target temperature under pressure, and (6) cooling at a controlled rate [8]. The pulsed nature of the current is believed to contribute to the cleaning of particle surfaces and the formation of particle-to-particle necks, enhancing mass transport during sintering [9].

Recent advancements in FAST technology have led to the development of MICRO-FAST, a process that enables the fabrication of miniaturised components with improved precision and performance [10]. MICRO-FAST integrates the principles of FAST with micro-forming techniques, allowing for the volume production of small-scale components with complex geometries and enhanced properties [11].

Building upon the foundational work of researchers like Yi Qin et al. who have demonstrated the potential of the FAST process for producing high-performance thermoelectric materials [12], this investigation extends the application of FAST to ZrNiSn-based half-Heusler thermoelectric material. The experimental methodology included a systematic investigation of the complete processing chain, including raw material preparation, field-assisted sintering technology (FAST) synthesis protocols, and comprehensive characterisation studies. This integrated approach facilitated an understanding of the fundamental relationships between FAST processing parameters and the resultant material properties.

Half-Heusler (HH) compounds have emerged as promising materials due to their unique crystal structure and tunable electronic properties among all the candidates for suitable thermoelectric applications. HH materials are a class of intermetallic compounds that exhibit promising thermoelectric properties, making them suitable for applications in thermoelectric generators (TEGs) and other energy conversion devices. These materials belong to the family of Heusler alloys, which are ternary compounds with a general chemical formula of XYZ, where X and Y are transition metals and Z is a main group element. Specifically, Half-Heusler compounds have the formula XNiSn (where X can vary), and they crystallise in a cubic structure. They are known for their high thermoelectric efficiency due to a combination of factors: high Seebeck coefficient, moderate electrical conductivity, and low thermal conductivity [13].

Traditional HH materials, such as ZrNiSn, exhibit excellent thermal stability and mechanical robustness, making them suitable for high-temperature TE devices [14]. These materials often contain hafnium (Hf) primarily because of its contribution towards electronic band structure optimisation, electrical conductivity enhancement, and thermoelectric figure of merit improvement. However, conventional formulations containing Hf face challenges with cost, availability, and environmental impact. In response, researchers have turned to Hafnium-free alternatives [15]. One such promising candidate is the powder (Zr0.4Ti0.6)0.33Ni0.33(Sn0.98Sb0.02)0.33, developed by powder specialist and manufacturer MBN Nanomaterialia Spa for the Horizon 2020 research project FAST-SMART. Titanium and antimony are chosen as substitutes for Hafnium due to their similar chemical properties and potential to be tuned to achieve comparable thermoelectric performance. This approach proposes substituting Hf with Ti in the Half-Heusler structure, aiming to maintain its beneficial properties. This new composition is expected to exhibit equivalent thermoelectric performance and better environmental compatibility than its Hafnium-containing counterparts.

This investigation applies FAST sintering to the Hf-free HH powder (Zr0.4Ti0.6)0.33Ni0.33(Sn0.98Sb0.02)0.33 for energy harvesting applications. To determine optimal processing conditions, this research systematically explores various sintering parameters, including sintering pressure, sintering temperature, holding time at target temperature, and heating rates. These parameters were strategically selected to achieve maximum relative density, which is critical for thermoelectric performance as porosity significantly degrades both mechanical stability and thermoelectric transport properties. In thermoelectric materials, high density minimizes phonon and electron scattering at void interfaces, ensuring optimal electrical conductivity while maintaining the desired thermal resistance characteristics necessary for high ZT values.

Comprehensive post-sintering analysis covers relative density measurements, thermal conductivity assessment, electrical resistivity evaluation, and Seebeck coefficient determination to characterise the sintered components' performance. These findings carry significant implications for advancing energy harvesting device efficiency and contributing to sustainable energy production objectives.

2 FAST sintering process, tools and experiments for ZrNiSn

This section provides a comprehensive overview of how field-assisted sintering technology (FAST) was applied to the n-type Half-Heusler thermoelectric material (Zr0.4Ti0.6)0.33Ni0.33(Sn0.98Sb0.02)0.33. It begins by exploring the specific FAST sintering methodology used in this study, detailing the setup of the sintering apparatus and die configuration. The section then introduces the powdered material utilised in the research. In addition, it examines key sintering parameters for this material, including sintering pressure, processing temperature, holding time, and heating rate. Through systematically analysing these variables, the study aims to establish optimised sintering conditions tailored to this material, forming a foundational basis for subsequent characterisation and performance evaluation.

2.1 Field-assisted sintering technology (FAST)

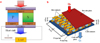

The sintering experiments in this study were performed using a Gleeble 3500 thermomechanical simulator (Dynamic Systems Inc.) located at Swansea University. The system's direct resistance heating capability, with maximum heating rates of 10,000 °C/s, enabled rapid thermal cycling conducive to grain refinement and enhanced densification. The integrated servo-hydraulic loading system, rated to 100 kN, provided the necessary uniaxial pressure control during sintering [16]. The experimental setup, including the main unit and vacuum chamber, is shown in Figure 2.

Precise sintering temperature control in this research is achieved through a dual-monitoring closed-loop thermal system. The system employs thermocouples embedded in the graphite die to measure the temperature closest to the powder compartment. This measurement is then cross-checked with a high-accuracy pyrometer positioned outside the chamber, as indicated in Figure 2a, to minimise measurement error. This configuration allows for precise temperature measurement and control with accuracies within ±1 °C. The sintering process was conducted in a protective atmosphere maintained by a vacuum chamber operating at a pressure level of 1×10−4 Torr, ensuring sample preservation during sintering.

The experimental setup incorporated purpose-built graphite tooling engineered specifically for the Gleeble system parameters (detailed specifications provided in Sec. 2.2). This assembly comprised a powder containment chamber formed by two punches and a die, and it is positioned between tungsten carbide electrodes within the vacuum environment.

The FAST process began with vacuum evacuation of the sealed chamber containing the mounted die assembly. Real-time temperature monitoring employed either K-type or R-type thermocouples, supplemented by non-contact pyrometric measurements through the chamber viewport. The progression of the sintering cycle was characterised by distinctive colour transitions of the graphite tooling assembly, corresponding to specific temperature ranges. These thermochromatic transitions are documented in Figure 3.

Figure 3 also illustrates a noteworthy phenomenon observed during the FAST process, namely, the movement of graphite punches. Initially, as depicted in Figure 3a, noticeable gaps exist between the die and the punches after powder loading. These gaps gradually diminish with increasing temperature and nearly disappear at peak temperatures (Fig. 3b,c). Upon cooling of the die, significant densification of the specimen is evident, as the gaps between the die and the two punches are substantially reduced compared to their pre-sintering levels (Fig. 3d).

Following the completion of the sintering cycle, the tooling assembly was removed and disassembled to extract the consolidated specimen. The resultant cylindrical compact, as shown in Figure 5c, underwent systematic materials characterisation to quantify its physical, thermal, and electrical characteristics. These analyses provided critical insights into both process efficiency and material viability for thermoelectric applications.

|

Fig. 2 Gleeble 3500 system and vacuum chamber. |

|

Fig. 3 Changes of die set during the FAST process. |

|

Fig. 4 CAD model of graphite die assembly (a) and design details (b). |

|

Fig. 5 Cylindrical Die (a), Punches (b) and Sintered Part (c). |

2.2 Sintering dies for FAST

The sintering apparatus incorporated custom graphite tooling specifically designed for the thermomechanical processing provided by the Gleeble system. The tooling configuration consisted of a primary die body with matching upper and lower punches. Temperature monitoring was facilitated through a precision-machined port in the die wall to accommodate thermocouple placement.

The specimen fabrication procedure involved sequential steps: initial bottom punch positioning, followed by staged powder loading with intermediate cold compression cycles to optimise green density distribution. Upon completion of powder loading and top punch insertion, the assembled tooling was mounted between tungsten carbide platens within the vacuum chamber, ensuring both electrical conductivity and uniform load transfer during processing.

As shown in Figure 4b above, the die has a tapered angle of 4 degrees, allowing for easy punch removal after high-temperature sintering. Figures 5a and 5b below indicates the manufactured die set. Graphite die sets with various diameters and punch designs were also developed to suit different materials and sample size requirements.

2.3 Thermoelectric module

Thermoelectric (TE) modules, also referred to as thermoelectric generators (TEGs), are devices that can collect and convert thermal energy into electricity. TEG based on half-Heusler materials are devices engineered to convert heat directly into electrical energy through the Seebeck effect. These modules typically comprise pairs of n-type and p-type half-Heusler semiconductor materials connected electrically in series and thermally in parallel, as illustrated in Figure 6.

In n-type half-Heusler semiconductors, such as ZrNiSn, electrons are the majority charge carriers. These electrons gain thermal energy and migrate from the hot side (high temperature) to the cold side (low temperature), generating an electrical potential difference. Conversely, p-type half-Heusler semiconductors, such as HfCoSb, have holes as the majority carriers. When subjected to heat, these holes move from the hot to the cold side, creating an electrical potential difference. The combination of n-type and p-type half-Heusler materials in a TE module ensures that when one side of the module is exposed to a heat source and the other to a heat sink, a voltage is produced across the module due to the temperature gradient. This voltage can then be harnessed to power electronic devices or stored in batteries [17]. The efficiency of a half-Heusler TE module depends on factors such as the thermoelectric properties of the materials used, the module's geometric design, and the magnitude of the temperature gradient applied.

2.4 n-type Hf-free half Heuslaer ZrNiSn powder

Half-Heusler alloys are among the most promising materials for thermoelectric generators as they can be used in a wide temperature range, and their abundant and inexpensive when hafnium (Hf) is involved.

Among n-type Half-Heusler TE materials, MNiSn (M=Ti, Zr, or Hf) with 18 valence electron count per unit cell and a narrow energy band gap has been researched extensively and shown to exhibit unique and tunable electrical transport properties. In recent years, researchers have realised a high ZT value of approximately 1.0 by reducing the grain size and extensive adoption of Hf [18]. However, the incorporation of the inclusion of Hf increases the cost, and its production is highly dependent on the availability of the rare earth element. To address this issue, MBN Nanomaterialia Spa substituted the Hf with Titanium and used the high-energy ball milling technique to produce the powder used in this study.

The Hf-free Half-Heusler thermoelectric material, n-doped ZrNiSn with chemical composition (Zr0.4Ti0.6)0.33Ni0.33(Sn0.98Sb0.02)0.33, was investigated using the FAST process. The formulation and structure of this material can be found in Figure 7.

|

Fig. 7 Formulation and structure of the Half-Heusler thermoelectric material (MBN Nanomaterialia® Spa). |

2.5 FAST sintering of the ZrNiSn material

Figure 8a details the specific sintering parameters applied to ZrNiSn, including temperature, heating rate, pressure, and holding time, each varied across three levels as part of a designed experiment. The Taguchi L9 orthogonal array design of experiment was used in this investigation, resulting in nine combinations. This method minimises the number of experiments, while effectively focusing on the main effects. These parameters were systematically varied to optimise the sintering process, aiming to identify this material's optimal combination of sintering conditions. The highest density achieved was 7.411g/cm3. Interestingly, visual inspection revealed that specimens with higher densities often exhibited surface imperfections. Figure 8b visually documents these characteristics of the sintered specimens, highlighting their structural integrity and surface quality.

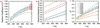

The factorial analysis conducted on the sintering parameters of (Zr0.4Ti0.6)0.33Ni0.33(Sn0.98Sb0.02)0.33 using the FAST process provides valuable insights into their respective impacts on density outcomes, as illustrated in Figure 9.

Sintering temperature emerged as the most influential parameter, accounting for 61.928% of the variance in density results. This finding underscores its critical role in controlling the kinetics of grain growth and phase transformation during sintering. A higher sintering temperature promotes greater atomic diffusion and facilitates densification, which is crucial for achieving high-density sintered materials.

Following closely, sintering pressure contributed significantly at 16.980%. Pressure during sintering affects particle packing and interparticle bonding, directly influencing the final density. Optimal pressure conditions help minimise voids and enhance material compactness, thereby improving overall density and mechanical strength.

Holding time, with a contribution of 12.580%, influences the duration of particle rearrangement and consolidation under heat and pressure. It allows sufficient time for diffusion processes to occur, ensuring adequate bonding between particles and contributing to densification.

In contrast, the heating rate, though the least impactful at 6.753%, remains essential for achieving uniform heating and controlling the rate of microstructural evolution. A moderate heating rate balances rapid densification and thermal stresses minimisation, which is crucial for preventing defects and ensuring uniform material properties.

The optimal conditions —900 °C sintering temperature, 15 MPa sintering pressure, 60 °C/min heating rate, and 15 minutes holding time have been identified to promote high-density sintering. It should be clarified that they may not necessarily optimise the thermoelectric performance of (Zr0.4Ti0.6)0.33Ni0.33(Sn0.98Sb0.02)0.33. Achieving the best overall thermoelectric properties requires balancing multiple factors, including electrical conductivity and thermal transport properties, which may require additional parameter optimisation.

|

Fig. 8 Design of Experiments (a) and sintered ZrNiSn (b). |

|

Fig. 9 Factorial analysis of sintering parameters. |

3 Characteristics of the sintered ZrNiSn parts

The following section presents a detailed analysis of sintered n-type (Zr0.4Ti0.6)0.33Ni0.33(Sn0.98Sb0.02)0.33 specimens produced via field-assisted sintering technology (FAST). These analyses assess and evaluate the efficiency of the FAST process for this bespoke material and provide a preliminary determination of the material's suitability for potential thermoelectric applications. The investigation encompasses four primary analytical domains: specimen preparation protocols, structural analysis (including density measurements and X-ray diffraction studies), thermal transport evaluation, and electrical characterisation.

The experimental methodology begins with specimen preparation, followed by density measurements and phase identification through XRD. Subsequent thermal conductivity studies assess heat transport behaviour, while electrical resistivity and Seebeck coefficient measurements quantify charge carrier dynamics. These analyses establish correlations between processing parameters and the resultant thermoelectric performance metrics.

3.1 Sample preparation

Specimen preparation protocols were followed to meet the dimensional and surface quality requirements for thermal and electrical property measurements. The processing sequence involved initial sectioning of the sintered compact followed by precision grinding to achieve final geometries. These procedures ensured appropriate sample dimensions and surface conditions for thermal conductivity, electrical resistivity, and Seebeck coefficient measurements. The detailed preparation procedures are presented in Table 1

Sample preparation for thermoelectric characterisation.

3.2 Relative density and XRD analysis

Relative density serves as a crucial indicator of the sintering process efficacy and sintered part quality. It can be calculated using the following relationship:

The relative density of sintered thermoelectric materials significantly impacts their transport properties and subsequent figure of merit (ZT). Dense microstructures facilitate efficient electrical transport, while the presence of residual porosity can impede charge carrier mobility and reduce overall electrical conductivity. Generally speaking, higher relative density is frequently correlated with improved thermoelectric performance, attributed to enhanced charge carrier mobility and reduced phonon scattering at grain boundaries. However, the relationship between density and thermoelectric performance is complex, as controlled porosity may contribute to phonon scattering and reduced thermal conductivity, potentially enhancing ZT under specific conditions. According to the specification provided by the powder manufacturer, the theoretical density of (Zr0.4Ti0.6)0.33Ni0.33(Sn0.98Sb0.02)0.33 was estimated to be 7.5829 g/cm3. This value is thus used to calculate the relative densities of the sintered samples.

The measured densities were determined using the Archimedes method, where samples were initially weighed in air and subsequently immersed in liquid to ascertain their volume. As shown in Figure 10a, sintered samples achieved relative densities of up to 97.73%. XRD analysis confirmed the absence of impurity phases, validating the successful synthesis of a single-phase (Zr0.4Ti0.6)0.33Ni0.33(Sn0.98Sb0.02)0.33 material through the FAST process, ensuring high crystalline purity and structural integrity.

|

Fig. 10 Relative densities of sintered ZrNiSn (a) and XRD analysis (b). |

3.3 Thermal conductivity

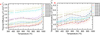

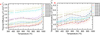

Thermal transport characteristics significantly impact thermoelectric device performance, with thermal conductivity playing a dominant role in energy conversion efficiency. However, thermal conductivity cannot be directly measured.Thermal diffusivity measurements are straightforward. In this study, the thermal diffusivity of sintered ZrNiSn was performed using laser flash analysis (LFA) via a Linseis LFA 1000 system, as shown in Figure 11a. This method evaluates thermal transport by analysing the temporal response of samples subjected to laser pulse excitation. The results are presented in Figure 12a.

The measured thermal diffusivity can then be converted to thermal conductivity using the following relationship.

where k (T) represents the calculated thermal conductivity, α (T) denotes the measured thermal diffusivity, ρ is the measured density, and cp is the specific heat of the material.

Using the equation above, the temperature-dependent thermal conductivity calculations of (Zr0.4Ti0.6)0.33Ni0.33(Sn0.98Sb0.02)0.33 specimens were conducted from 300 K to 1000 K, as illustrated in Figure 12b. The results demonstrated a direct correlation between specimen density and thermal conductivity, attributed to enhanced phonon transport in specimens with reduced porosity. This relationship provides a strong foundation for producing thermoelectric modules with desired thermal conductivity. While higher thermal conductivity is desirable for heat transfer applications, lower thermal conductivity typically is typically beneficial for thermoelectric applications such as TEGs, by maintaining more significant temperature gradients across the active elements.

|

Fig. 11 Linseis system used in this study − LFA 1000 (a) and LSR-3 (b). |

|

Fig. 12 Measured thermal diffusivity (a) and calculated thermal conductivity (b). |

3.4 Electrical resistivity and Seebeck coefficient

The thermoelectric performance evaluation focused on electrical transport characteristics and Seebeck coefficient measurements, conducted using a Linseis LSR-3 system, as shown in Figure 11b. The apparatus employs a four-point probe method for resistivity determination and generates controlled thermal gradients for Seebeck coefficient analysis.

The figure of merit for thermoelectric generators (TEGs), denoted as ZT, is a dimensionless parameter that measures the efficiency of a thermoelectric material in converting heat into electrical energy. It is defined as

where s represents the Seebeck coefficient, σ denotes electrical conductivity, k indicates thermal conductivity, and T is absolute temperature. Higher ZT values indicate improved thermoelectric efficiency. The above-mentioned relationship has three critical transport parameters: Seebeck coefficient (S), electrical conductivity (σ = 1/ρ), and thermal conductivity (κ). The product S2σ, known as the power factor, characterises the electrical transport capability of thermoelectric materials.

The Seebeck coefficient (V/K) quantifies voltage generation in response to temperature gradients, reflecting carrier concentration and band structure characteristics. Electrical resistivity (ρ) influences charge transport efficiency, with lower values facilitating improved electrical performance. However, these parameters exhibit an inherent trade-off: increasing carrier concentration to carrier concentration that enhance conductivity often reduce the Seebeck coefficient.

Therefore, optimising the power factor (S2σ) requires carefully balancing these competing transport mechanisms. Ideal thermoelectric materials combine high power factors with low thermal conductivity, enabling efficient thermal-to-electrical energy conversion while preserving significant temperature gradients. As shown in Figure 13c that samples with maximum relative density do not necessarily exhibit the highest ZT due to a corresponding increase in thermal conductivity.

Analysis of the experimental data represented in Figures 13a–13c revealed several key findings. The expected Seebeck coefficient for (Zr0.4Ti0.6)0.33Ni0.33(Sn0.98Sb0.02)0.33 at 500 °C is approximately −170 μV/K, with an average figure of merit of 0.65 between 100 and 500 °C, according to information provided by the powder manufacturer. However, measured Seebeck coefficient values range between −110 to −125 μV/K at this target temperature range. Notably, the sample with the lowest density exhibits the poorest Seebeck coefficient. Interestingly, the highest-density samples do not necessarily show the best Seebeck coefficient, as they tend to have higher thermal conductivity, leading to increased heat loss and negatively impacting the Seebeck effect.

In terms of electrical resistivity, samples 1, 2, and 3 exhibit the poorest performance, attributed to their lower densities and lowest processing temperature. Samples 4 and 6, sintered at 800 °C, show similar densities to samples 1 and 3 but demonstrate significantly improved electrical resistivity compared to those processed at 700 °C. Samples 7, 8, and 9, sintered at 900 °C, exhibit the best electrical performance, underscoring the dominant role of sintering temperature in achieving higher electrical conductivity.

Regarding the figure of merit, the highest average value achieved is approximately 0.3 across the temperature range, with a maximum value of ∼0.54, slightly above 500 °C. The sample achieving the best ZT value has a relative density of 94.54%, which ranks third highest among all samples in terms of relative density.

|

Fig. 13 Measured Seebeck coefficient (a), electrical resistivity (b) and calculated figure of merit (c). |

4 Discussion

The figure of merit for the Hf-free Half-Heusler thermoelectric material (Zr0.4Ti0.6)0.33Ni0.33(Sn0.98Sb0.02)0.33 does not align with the manufacturer's expectations, prompting further analysis of factors ranging from powder chemistry, high-energy ball milling, and synthesis protocols. Despite these challenges, this study significantly advances the understanding of the FAST process applied to this novel powder. It underscores the critical role of sintering temperature in achieving higher densities and better electrical conductivities in the sintered samples.

For an ideal thermoelectric generator (TEG), optimising properties such as the Seebeck coefficient, electrical conductivity, and thermal conductivity is essential. This study reveals that sintered samples with higher densities exhibit promising electrical conductivity. However, this comes at the expense of increased thermal conductivity and reduced Seebeck coefficient. Nevertheless, samples with higher densities generally exhibit superior mechanical properties and are favoured in commercial applications.

The trade-off between pursuing higher densities and achieving an optimal figure of merit for TEG applications necessitates careful consideration. Balancing these competing factors is crucial for advancing thermoelectric materials toward practical and scalable energy conversion technologies.

5 Conclusions

In this study, the efficacy of field-assisted sintering technology was successfully demonstrated for sintering the Hafnium-free Half-Heusler thermoelectric material (Zr0.4Ti0.6)0.33Ni0.33(Sn0.98Sb0.02)0.33. We identified optimal FAST conditions crucial for achieving high density and superior material properties through systematic variation of sintering parameters such as sintering pressure, temperature, holding time, and heating rates.

The comprehensive characterisation of the sintered materials, encompassing measurements and calculations of relative density, thermal conductivity, electrical conductivity, and the Seebeck coefficient, validated the effectiveness of the FAST process in enhancing the performance of thermoelectric ceramics. This research significantly contributes to advancing the understanding and application of the FAST process, laying a solid foundation for the development of advanced materials with enhanced properties crucial for the next generation of energy harvesting systems.

Furthermore, this study represents a significant step forward in the search for Hafnium-free Half-Heusler thermoelectric generators, contributing to ongoing efforts in sustainable materials research. The findings underscore the versatility and effectiveness of the FAST process in producing high-quality thermoelectric ceramics, present a robust platform for continued innovation and research and providing a robust platform for further research and development.

Acknowledgments

The authors gratefully acknowledge the European Commission for the financial support for conducting the research through the EU FAST-SMART Project (Grant Agreement number: 862289). Special thanks are also extended to the Swansea University for granting the access to the Gleeble 3500 thermomechanical system, and Heriot-Watt University for the invaluable support in the sample characterisation in this research. The authors would also like to express appreciation to MBN Nanomaterialia Spa, Italy, for supplying the powder used in this study, Pascoe Engineering Ltd., UK, for their work in the tool fabrication, and other EU project partners for knowledge exchanges through the FAST-SMART project.

Funding

This research (FAST-SMART) has received funding from the HORIZON2020 Framework Grant Agreement no. 862289.

Conflicts of interest

The authors declare no conflicts of interest.

Data availability statement

The data supporting this article is included within the article.

Author contribution statement

Bo Chen: Experiment, Analysis and Writing − original draft preparation; Yankang Tian: Experiment, Analysis − review and editing; Wenlong Chang: Experiment, Analysis − review and editing; Jie Zhao: Experiment − review and editing; Song Yang: Experiment − review and editing; Xingguo Zhou: Experiment − review and editing; Alvise Bianchin: Experiment − review and editing; Yi Qin: Supervision, Resources − review and editing.

References

- G.J. Snyder, E.S. Toberer, Complex thermoelectric materials, Nat. Mater. 7 (2008) 105–114 [CrossRef] [PubMed] [Google Scholar]

- S. Priya, D.J. Inman, Energy Harvesting Technologies, Springer US 2009. https://doi.org/10.1007/978-0-387-76464-1 [Google Scholar]

- O. Guillon, J. Gonzalez-Julian, B. Dargatz et al., Field-assisted sintering technology/spark plasma sintering: Mechanisms, materials, and technology developments, Adv. Eng. Mater. 16 (2014) 830–849 [CrossRef] [Google Scholar]

- E.A. Olevsky, D.V. Dudina, Field-Assisted Sintering: Science and Applications, Springer International Publishing, 2018. https://doi.org/10.1007/978-3-319-76032-2 [Google Scholar]

- R. Orrù, R. Licheri, A.M. Locci et al., Consolidation/synthesis of materials by electric current activated/assisted sintering, Mater. Sci. Eng. R Rep. 63 (2009) 127–287 [Google Scholar]

- Z.H. Zhang, Z.F. Liu, J.F. Lu et al., The sintering mechanism in spark plasma sintering − Proof of the occurrence of spark discharge, Scr. Mater. 81 (2014) 56–59 [Google Scholar]

- SINTERMAT, FAST sintering: a new process, more efficient than traditional sintering, https://sinter-mat.com/en/fast-sintering-3/ (accessed 25 October 2024) [Google Scholar]

- M. Suarez, A. Fernandez, J.L. Menendez et al., Challenges and opportunities for spark plasma sintering: A key technology for a new generation of materials, in: Sintering Applications, InTech, 2013. https://doi.org/10.5772/53706 [Google Scholar]

- S. Grasso, Y. Sakka, G. Maizza et al., Pressure effect on the homogeneity of spark plasma-sintered tungsten carbide powder, J. Am. Ceram. Soc. 92 (2009) 2418–2421 [Google Scholar]

- K. Huang, Y. Qin, J. Zhao et al., Fabrication of NiTi shape memory alloy by Micro-FAST, MATEC Web Conf. 21 (2015) 10003 [Google Scholar]

- K. Huang, Y. Yang, Y. Qin et al., Densification behavior of copper powder during the coupled multi-physics fields-activated microforming, Int. J. Adv. Manuf. Technol. 69 (2013) 2651–2657 [Google Scholar]

- Y. Yang, K. Huang, G. Yang et al., Micro-sintering through a FAST process, in: Micromanufacturing Engineering and Technology, 2nd ed., Elsevier Inc., 2015, pp. 257–276. https://doi.org/10.1016/B978-0-323-31149–6.00011–6 [Google Scholar]

- J.K. Kawasaki, S. Chatterjee, P.C. Canfield, Full and half-Heusler compounds, MRS Bull. 47 (2022) 555–558 [Google Scholar]

- Q. Shen, L. Zhang, Thermoelectric properties of ZrNiSn-based half-Heusler compounds by solid state reaction method, J. Mater. Sci. Lett. 20 (2001) 2197–2199 [Google Scholar]

- Q. Zhang, P. Xie, C. Liu et al., Enhanced thermoelectric performance of hafnium-free n-type ZrNiSn half-Heusler alloys by isoelectronic Si substitution, Mater. Today Phys. 24 (2022) 100648 [Google Scholar]

- Dynamic Systems Inc., Gleeble® 3500 −GTC system, https://gleeble.com/products/gleeble-systems/gleeble-3500.html (accessed 25 October 2024) [Google Scholar]

- N. Jaziri, A. Boughamoura, J. Müller et al., A comprehensive review of thermoelectric generators: Technologies and common applications, Energy Rep. 6 (2020) 264–287 [Google Scholar]

- G. Rogl, P. Sauerschnig, Z. Rykavets et al., (V,Nb)-doped half-Heusler alloys based on {Ti,Zr,Hf}NiSn with high ZT, Acta Mater. 131 (2017) 336–348 [Google Scholar]

Cite this article as: Bo Chen, Yankang Tian, Wenlong Chang, Jie Zhao, Song Yang, Xingguo Zhou, Alvise Bianchin, Yi Qin, Field-assisted sintering process and part characterisation of hafnium-free half Heusler thermoelectric material ZrNiSn, Manufacturing Rev. 12, 18 (2025), https://doi.org/10.1051/mfreview/2025010

All Tables

All Figures

|

Fig. 1 Schematic of field-assisted sintering technology [7]. |

| In the text | |

|

Fig. 2 Gleeble 3500 system and vacuum chamber. |

| In the text | |

|

Fig. 3 Changes of die set during the FAST process. |

| In the text | |

|

Fig. 4 CAD model of graphite die assembly (a) and design details (b). |

| In the text | |

|

Fig. 5 Cylindrical Die (a), Punches (b) and Sintered Part (c). |

| In the text | |

|

Fig. 6 Thermoelectric material to arrangements (a) and TEG design (b) [17]. |

| In the text | |

|

Fig. 7 Formulation and structure of the Half-Heusler thermoelectric material (MBN Nanomaterialia® Spa). |

| In the text | |

|

Fig. 8 Design of Experiments (a) and sintered ZrNiSn (b). |

| In the text | |

|

Fig. 9 Factorial analysis of sintering parameters. |

| In the text | |

|

Fig. 10 Relative densities of sintered ZrNiSn (a) and XRD analysis (b). |

| In the text | |

|

Fig. 11 Linseis system used in this study − LFA 1000 (a) and LSR-3 (b). |

| In the text | |

|

Fig. 12 Measured thermal diffusivity (a) and calculated thermal conductivity (b). |

| In the text | |

|

Fig. 13 Measured Seebeck coefficient (a), electrical resistivity (b) and calculated figure of merit (c). |

| In the text | |

Current usage metrics show cumulative count of Article Views (full-text article views including HTML views, PDF and ePub downloads, according to the available data) and Abstracts Views on Vision4Press platform.

Data correspond to usage on the plateform after 2015. The current usage metrics is available 48-96 hours after online publication and is updated daily on week days.

Initial download of the metrics may take a while.