| Issue |

Manufacturing Rev.

Volume 11, 2024

|

|

|---|---|---|

| Article Number | 5 | |

| Number of page(s) | 10 | |

| DOI | https://doi.org/10.1051/mfreview/2024004 | |

| Published online | 19 March 2024 | |

Research article

Influence of sintering temperature on Ti6Al4V-Si3N4-ZrO2 ternary composites prepared by spark plasma sintering

Centre for Nanoengineering and Advanced Materials, Department of Metallurgy Engineering, University of Johannesburg, South Africa

* e-mail: ogunmefunolakunleanthony@yahoo.com

Received:

17

November

2023

Accepted:

30

January

2024

In this study, Ti6Al4V-ZrO2-Si3N4 ternary composites were fabricated using a novel spark plasma sintering technique at different temperatures between 950-1200 °C, the pressure of 50 MPa, sintering rate of 100 °C/min, and a holding time of 10 min to determine the effect of sintering temperature on the consolidated composites. The microstructures of the fabricated composites were examined by the scanning electron microscope (SEM-EDX). The distinct phases and the nano-mechanical properties of the composite were determined by the X-ray diffractometer and nanoindenter. The results show a non-linear response. At elevated temperatures from the composite sample, CT1-950 °C to the composite sample, CT2-1100 °C, the densification, and nanomechanical properties experienced an increase, and when the temperature is elevated to 1200 °C, composite CT3 declines in values. However, the relative density of all fabricated composites was above 95%, which suggests an overall good densification via the spark plasma sintering technique. The ternary composite fabricated at 1100 °C, (CT2) attained maximum values of Vickers hardness, elastic modulus, and nano hardness at 7380 MPa, 177.91 GPa, and 60.06 GPa, respectively, while composite CT3 declines at 1200 °C.

Key words: Pulsed electric current sintering / Ti6Al4V / Zirconia / Si3N4 / nanomechanical properties

© A.O. Ogunmefun et al., Published by EDP Sciences 2024

This is an Open Access article distributed under the terms of the Creative Commons Attribution License (https://creativecommons.org/licenses/by/4.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

This is an Open Access article distributed under the terms of the Creative Commons Attribution License (https://creativecommons.org/licenses/by/4.0), which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited.

1 Introduction

Scientists and scholars in material technology have used novel fabrication processes to get around several obstacles in the process of creating cutting-edge materials and adapting them for various uses. Over the years, this innovation has turned out to be a breakthrough in the manufacturing and engineering industries. Commercially available titanium alloys continue to be a preferred material used in technological industries because of their superior mechanical properties and are normally processed thermo-mechanically to provide the appropriate microstructure for their application [1].

Titanium matrix composites have gained wide recognition because of their excellent mechanical properties, and they have been employed extensively in manufacturing structural parts for the automotive, submarine, biomedical, aircraft, and other technical sectors [2,3]. According to reports, Ti-6Al-4V, a typical α/β titanium alloy, is the most used titanium alloy [4]. The weak tribological qualities caused by the low hardness, a high coefficient of friction, and corrosion characteristics, however, prohibit the titanium alloy from being used in many more applications as it degrades at high temperatures, which limits its use in situations where improved mechanical qualities at high temperatures are essential [5,6]. Researchers worldwide are still very interested in improving the overall properties of Ti-6Al-4V alloy by chemical and physical modification. Determining the qualities of the composites also heavily depends on the choice of manufacturing technique. To ameliorate these challenges, research was done to increase the service life of titanium alloys against heat, wear, and corrosion. Numerous surface treatment techniques have been developed and put into use recently to enhance the thermo-mechanical qualities of titanium alloys. The majority of these exterior amendment procedures, such as Self-Propagating High-Temperature Synthesis (SHS), Excimer Laser Surface, and Plasma-Enhanced Vapour Deposition Coating, have been created to enhance this metal's structural and mechanical capabilities [7]. “Potentially, the Powder Metallurgy (PM) process, via the spark plasma sintering (SPS), fabrication procedure, also called pulsed electric current sintering, is the most successful technique that has attracted so much attention in recent years due to the benefit of a homogeneous dispersal of ceramics in the matrix at short-time, low-pressure, and high-density as compared with the other traditional sintering processes [8]. It enables the production of bulk materials from powders employing high heating rates (up to 1000 °C/min) and brief holding durations at low sintering temperatures lower than most conventional sintering methods [9]”. Figure 1 illustrates a typical sintering process of consolidating metallic powder and ceramics.

The creation of composite materials with Zirconia (ZrO2) matrix is a response to the development of novel materials with improved, cutting-edge qualities like high thermal shock and fracture resistance, etc. Titanium alloys, such as Ti-6Al-4V are a good component for ZrO2-based composites, particularly for aeronautics and biomedical application areas because of their potential characteristics of high chemical resistance, high fatigue resistance, biocompatibility, and high melting point [10]. The characteristics of ZrO2 make it a very attractive ceramic product with a broad range of applications in science and technology [11]. Although the hardness and stiffness of composite materials are reduced when ZrO2 ceramic materials are added to titanium alloy [12], ZrO2 as reinforcement enhances the fracture toughness of the composites [13].

Also, one of the few monolithic ceramic materials that can tolerate high thermal shock and temperature changes in the synthetic silicon nitride family is Si3N4 [14]. Such innate properties exhibited by Si3N4, viz high flexural strength, outstanding creep resistance, high hardness features, etc., are only a few of many exceptional properties, as an advanced structural ceramic. However, traditional Si3N4 ceramic suffers from weak fracture toughness, which results in low damage tolerance and poor reliability, like most ceramics. The inclusion of particulate ZrO2 as reinforcement has been shown to improve ceramic fracture toughness, with reinforcing procedures primarily based on stress-induced martensitic tetragonal-monoclinic transformation and microcrack toughening [15]. As a quick method of assessing the mechanical characteristics of various materials (metals, composites, polymers, coatings, films, etc.) without affecting the microscopic structure as well as other characteristics of the materials, nanoindentation is currently gaining attention [16,17]. The bulk characteristics of TMCs have been the subject of numerous research investigations [18]. However, when materials-material interactions are in use, the top layer of a material acts as the primary interface for interaction. Thus, it is necessary to analyse the surface characteristics of the created TMCs to offer appropriate and correct statistics to supplement the database of core properties of TMCs that are currently available in the literature.

The SPS approach has been used by many researchers to study the effects of adding ceramic particles to Ti-alloys on their mechanical and tribological properties. To improve the microstructural features and mechanical performances of the sintered composites, Akinwamide et al. [19] consolidated YSZ/Si3N4 ceramic with Ti6Al4V alloy, the fabricated composites experienced great enhancement of micro- and nanomechanical properties of the reinforced Ti-6Al-4V matrix and the improvement was attributed to the load transfer mechanism between the matrix and the reinforcement phases during spark plasma sintering process. Also, in an attempt to examine the impact of reinforcements on the high-temperature oxidation of Ti-based composites, Kgoete et al. [20] studied the effects of silicon-nitride (Si3N4) as reinforcement on Ti6Al4V. The findings demonstrated that the microstructural and mechanical features of titanium-ceramic matrix composites were enhanced, and different bulk characteristics were obtained based on the additive's volume percentage. The ternary of Ti6Al4V, ZrO2, and Ni sintering was processed and examined by Obadele et al. [21] using SPS technology. It was discovered that the ZrO2 reinforcement had a significant impact on the microstructure and hardness of the fabricated composites via the generation of dispersoids, which acted as a pinning force within the neck zone. Within the grain boundary. Nickel-rich globules that were uniformly dispersed were also visible due to the microstructural morphology. Additionally, it is noteworthy to mention that the major factor in determining the load-transfer effect between the matrix and reinforcement particles is the size of the reinforcement particles. Metal matrix composites' strength and hardness have been demonstrated to improve as the size of the reinforcing particles decreases [22,23].

The goal of this work is to examine the microstructural evolution and nanomechanical performance of the ternary Ti-6Al-4V/ZrO2/Si3N4 synthesized using the spark plasma sintering process at 950 °C, 1100 °C, and 1200 °C sintering temperatures. Generally, there is a dearth of literature on the effects of ZrO2 and Si3N4 reinforcements on Ti-6Al-4 V alloy.

|

Fig. 1 A typical schematic diagram of SPS sintering. |

2 Methodology

In this study, the admixed powders were supplied by Alfa Aesar. Ti6Al4V was used as the matrix material, and the ceramics compounds were used as the reinforcement materials. With the aforementioned excellent properties, α-phase Si3N4 (APS: 0.88 μm; Purity: 99%); and ZrO2 (APS: 44 μm; Purity: 99%) powders were weighed and mixed with pre‐alloyed Ti–6Al–4V alloy powder of mean particle size, ∼30 µm. The powders were blended in a tubular mixer, accordingly with fractional volume percentage, viz Ti6Al4V-5%Si3N4-4%ZrO2, and then subjected to translational movements for 8 h at a relative speed of 60 rpm in a dry environment. Subsequently, the admixed particles were loaded inside the 30 mm diameter graphite dies, lined with flexible graphite foils for ease of removal of spark plasma sintered, SPSed composites inside the spark plasma sintering furnace (‘HHPD, 25 FCT Systeme, GmbH, Germany’). The composites CT1, CT2, and CT3 specimens underwent sintering temperature regimes, 950, 1100, and 1200 °C respectively at an external pressure of 50 MPa for 10 mins at 100 °C/min sintering rate. “The fabricated samples were cooled to the ambient temperature in the SPS furnace before their removal for a sandblasting operation to remove any residual layer of graphite that may result in carbon contamination of the sample surface. Figure 2 depicts the morphological characterization of the as-received raw material powders. The SEM micrograph in Figure 2a reveals non-porous spherical particles of Ti6Al4V alloy [24], Figure 2b shows around (with hollow doughnut-like) morphology with many satellites of ZrO2, and Figure 2c reveals hexagonal prism particles of Si3N4 [25]. The consolidation of the powders was thus carried out according to the earlier mentioned parameters”.

|

Fig. 2 SEM micrographs of starting materials. (a) Ti-6Al-4V, (b) ZrO2, and (c) Si3N4. |

2.1 Characterization of sintered composites

Using an Anton Paar DMA 5000 density meter, based on Archimedes' principle, the relative density of the sintered samples was measured for all samples. The effective density of each sample was determined using the arithmetic mean of six subsequent readings, and the theoretical density was determined using the rule of mixture. The ratio of effective density to theoretical density was then multiplied by 100% to determine the relative density of each sample [20]. The composite samples were subjected to the crystallographic process using the standard techniques of grinding, polishing, and, but with a mild etching. Phase characterization and microstructural morphology of the sintered composites were carried out using an X-ray diffractometer (PANalytical Empyrean) and field-emission scanning electron microscopy (FESEM JEOL JSM-7900F) equipped with energy-dispersive X-ray spectroscopy (EDS).

2.2 Nanoindentation measurement of SPSed composites

The nanoindenter tester TTX − NHT3, Switzerland, was used to determine the nano-mechanical characteristics of the as-sintered CT1, CT2, and CT3 composite specimens. This sophisticated apparatus makes use of a diamond Berkovich indenter in the form of a pyramid, and the analysis was carried out following ISO 14577 [26]. The indentation testing involved six total indentations in a 2 × 3-point grid. The space between each indentation point is 3 μm. The specimen was subjected to an indenter's peak load (Pmax) of 100 mN. To achieve this limit, the load was applied at a rate, of 300 mN/min. The maximum load was held for 20 s before being released at the same rate, which is the same rate as loading. The displacement of the indenter was continuously monitored, and a load-time history of the indentation was recorded. The fundamental material properties that were obtained from the nanoindentation data include Vicker's indentation hardness values, nano hardness, elastic modulus, elastic recovery index, plasticity index, elastic strain failure, and yield pressure. These parameters were found by using the load-displacement curve and the Oliver and Pharr technique [27].

3 Results and discussion

The SEM, EDS spectra, and elemental composition of the SPSed composites at temperatures 950, 1100, and 1200 °C are displayed in Figure 3. The backscattered electron micrographs show the contrasted microstructural characteristics and phase constituents unique to the three SPSed composites. It also reveals the distinct micrographic representation of each composite, CT1, CT2, and CT3. The BSE pictures show sites with lower atomic density (Si3N4) in the dark sections, while the lighter region of the microstructure shows sites with higher atomic density (ZrO2), and the grey portion most likely indicates the existence of the Ti6Al4V phase. As observed in the microstructures, the composite's particles are uniformly dispersed throughout the microstructure with the primary constituents/phases. As seen through the images, it was found that when the temperature was elevated, α-Ti and β-Ti phase layers grew closer to one another. Higher sintering temperatures may result in increased grain boundary migration and grain advancement due to the relative rise in density [28]. In Figure 3a, the reinforcement particles appear coarser in the composite specimens, with evidence of some porous craters in the microstructures, but as the temperature rises beyond CT1 sintering temperature, densification increases along with grain movement in Figure 3b, which eventually causes pores to close as expected. Consequently, an increase in sintering temperature caused the development of the grain size while only a modest increase in the solidified composite was observed. In Figure 3b, a uniform matrix dispersion of the ceramic reinforcement particles is seen at an elevated temperature of 1100 °C with a more homogeneous composite, free of porosity or cracks in the microstructure of the sintered composite. An agglomeration of the zirconia phase was however seen in the microstructure, which is not an aberration in the consolidation process during sintering, which is a consequence of a recrystallization process. Composite also reveals better consolidations of powders, and porosity inevitably reduces also. A similar case was also reported by Babapoor et al. [29,30]. As the temperature rises in Figure 3c, the sintered necks appear to grow and the densification zone expands further, and the grains appear coarser in the composite specimens with more porosity, as revealed in the microstructure. The relative density and mechanical properties of the composite are expected to increase when the sintering temperature is above 950 °C, because the grains expand quickly and the pores are completely removed, leading to the creation of substantially sealed pores [31], as seen in the case of CT2 at 1100 °C. Poor interfacial bonding [32] between the ceramics and titanium alloy particles, ineffective bonding [33], and weak metallurgical link [34], as a result of insufficient sintering settings are a few of the conditions that could contribute to its sinterability at elevated temperature, and amongst other factors. These elements may have an impact on the mechanical properties of sintered composite at different temperatures through microstructural changes.

The EDS layers/mappings in Figures 3a, 3b, and 3c reveal the elemental composition of phases inherent in the microstructures of the sintered (CT1, CT2, and CT3) composites at their respective temperatures. The distribution of these phases viz, Ti, Zr, Al, V, Si, and O are represented with the mappings/colorations showing the dispersion of the matrix-reinforcement composition within their respective microstructures.

|

Fig. 3 (a) SEM, EDS spectra, and elemental mapping of the SPSed composite CT1-950 °C, (b) Elemental mapping/EDS spectra of the SPSed composite CT2-1100 °C, (c) SEM, EDS spectra, and elemental mapping of the SPSed composite CT3-1200 °C. |

|

Fig. 3 (Continued). |

4 XRD phase identification

The X-ray diffractograms of sintered ternary composites, Ti6Al4V-5% Si3N4-4% ZrO2, consolidated at sintering temperatures CT1, 950 °C, CT2, 1100 °C, and CT3, 1200 °C are shown in Figure 4. From the micrographs, it is discovered that none of the diffractograms showed any discernible peak broadening, which means that no reaction occurred at the beginning of the sintering process, possibly as a result of internal strain in the powders owing to the ultra-fine grain size of the starting powder [35]. At prescribed temperatures, the peaks of elemental and interfacial phases were exposed. Prevalently, the phases were found to overlap with a noticeable peak intensity, which confirmed a unique phase evolution of composites. It was claimed that the two main strategies for enhancing the mechanical properties of composites were preventing the formation of grains and managing the contact between the matrix and additive. As a result, increasing the interface bonding in Ti-based composites is greatly influenced by the creation of an in-situ second phase. It is anticipated that these in-situ phases will provide a dislocation barrier within the matrix-reinforcement composition's grain boundaries causing strengthening of the composites [36], and by extension, increasing the mechanical property indices. A closer look at the XRD peaks of these results shows that samples at 950 °C and 1200 °C have similarities in terms of the composition of their phases, while samples at 1100 °C revealed a sparing presence of Si3N4 phases. This observation is further bolstered by the absence of Ti2N in the 1100 °C composite, unlike the 950 °C and 1200 °C cases where Ti2N is significantly present. The relative presence of Ti2N and Si3N4 could indicate the degree of interfacial bonding events that possibly occurred between the primary composite's powders of Ti6Al4V and Si3N4 during sintering. Notably during sintering, the neck formation and grain growth are usually mediated by the process of co-segregation of atoms from the two adjoining powder particles, leading to the evolution of an interface possibly characterized by a phase of unique composition [8]. However, it was determined that the thermochemical process caused the Ti2N and SiO2 phases to emerge as a densifier, furthering the densification of the composites (CT1, CT2, and CT3). The phases of Al and V at their respective temperatures were not noticeable, which may have been due to the low percentage composition of the complete phases that rendered them undetectable.

|

Fig. 4 X-ray diffractograms of SPSed Ti6Al4V-5%Si3N4-4%ZrO2 composites at temperatures 950 °C (CT1), 1100 °C (CT2), and 1200 °C (CT3). |

5 Evaluation of mechanical properties

5.1 Relative density of sintered composites

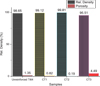

The relative density and porosity of the fabricated composites at different temperatures are presented in Figure 5 with distinctive colorations, identifying each composite at respective temperatures. As revealed in the chart, the relative density for the unreinforced sample is 98.65%, which implies that porosity prevented the sample from being completely densified, as other fabricated composites like CT3 with the lowest outcome at 95.51%, and CT1 with less porosity at 99.12%. Near full densification of 99.81% was attained with composite CT2 at a sintering temperature of 1100 °C from this study. The reduction in the porosity level upon the addition of the reinforcement could be connected to the sintering temperature adopted in this study as confirmed [37], which increases the material's density. Teber et al. [38] also confirmed that a lower porosity level for composites is indicative of a higher relative density, which increases their material efficiency to improve their mechanical performance. Interestingly, as a result of varying reinforcing particle sizes of the ceramics in the Ti-alloy matrix of this investigation, complete compaction during mixing and sintering operations may also not have been achieved, which could account for the quick drop in densification, as seen in CT3, coupled with the closed pores formed when intergranular pores are formed during high-temperature sintering [39] at 1200 °C of the composite. The Ti-6Al-4 V matrix's strong diffusivity of the reinforcement particles, on the other hand, is responsible for the specimen CT2's comparatively higher density measured at 1100 °C.

|

Fig. 5 Relative density and porosity graph for sintered composites CT1, CT2, and CT3. |

5.2 Nanomechanical and anti-wear characteristics of the sintered composites

Table 1 shows the mechanical properties of the study, as measured by an Anton Paar Hit 300 nanoindentation tester using a Berkovich diamond indenter following ASTM E2546. From the table, the Vickers hardness, elastic modulus, and nano hardness of composites, CT2, attained maximum values of 7380 MPa, 177.91 GPa, and 60.06 GPa respectively, but at the minimum when the sintering temperature in CT3 reached 1200 °C. This can be related to the rapid expansion of grains as a result of elevated temperature from 950 to 1100 °C, which prevents the pores from being completely removed, leading to the creation of significant sealed pores [31].

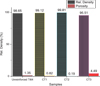

Table 1 shows the nanoindentation data of sintered composite, CT1, CT2, and CT3 at their respective 950, 1100, and 1200 °C sintering temperatures. The nano-hardness values recorded 55.19, 60.06, and 39.52 GPa, respectively, suggesting composite CT2 with a sintering temperature of 1100 °C to have the best nano-hardness value, while CT3 recorded the lowest. The Vickers hardness and modulus of elasticity values are corresponding, following the same trend as the nano hardness result. Interestingly, both densification and mechanical properties of this study are seen to have exhibited a nonlinear relation with the sintering temperature influence. François et al. [40] confirmed the parameters of volume fraction elemental powder composition, and the ceramic reinforcement configurations of composites to be responsible for the non-linear behavioural pattern [41]. The high stiffness/elastic modulus of CT2 sintered composite can allude to the equal volume fraction of the Si3N4/ZrO2 ceramic reinforcement of the ternary composite, which triggered multiple exothermic (in-situ) reactions with the base matrix during sintering process [25], as mentioned earlier. The reduction in the nano-hardness value recorded for samples CT1 and CT3 as compared to CT2 may be a result of segregation and coalescence [42] experienced during sintering, as well as a poor metallurgical fusion between the titanium alloy and ceramic particles encountered in this study, which might be attributed to the increased ceramic concentration [34,43,44]. Figure 6 displays the ratio-value-plot graphical relationship of yield pressures and the elastic strain to failure of the tri-sintered composites. This graph represents the scientific illustration of material resistance exhibited by the manufactured composites, to plastic deformation, which also shows that sample CT2 sintered at 1100 °C as having the highest resistance to strain and deformation, while CT1 has the least of the fabricated composites.

Nano-mechanical readings for sintered composite, Ti6Al4V-5% Si3N4-4% ZrO2 at CT1-950, CT2-1100, and CT3-1200 °C.

|

Fig. 6 Graphical representation of yield pressure & elastic strain of composites CT1, CT2, and CT3. |

6 Conclusion

This study on influence of sintering temperature on ceramics reinforced titanium alloy via spark plasma sintering technique led to microstructural and nanomechanical examinations.

From this inquiry, the following observations were made:

The spark plasma sintering technique was effective and successful process adopted for the consolidation of the experimentation.

Secondary in-situ phases, SiO2 and Ti2N, emerged during sintering process significantly improved the mechanical properties of the sintered samples produced.

The addition of ceramic reinforcements improved the samples' relative density, Vickers microhardness, nano hardness, and elastic modulus.

Sintered composite CT2-sample at 1100 °C demonstrated better relative density and nanomechanical properties than CT1-950 °C and CT3-1200 °C consequent upon an increasing interface bonding between matrix-reinforcement composite.

The enhancement of micro-nano properties of the reinforced Ti-6Al-4V composites was attributed to the load transfer mechanism between the matrix and the reinforcement phases.

The ternary composites consolidated at 1100 °C in this study is applicable to the aerospace and automotive industries, especially in the manufacturing of high-temperature strength engines

Funding

No funds, grants, or other support was received.

Conflict of interest

The authors declare no Conflict of interest.

Availability of data and materials

Data will be made available on request.

Author contribution

Ogunmefun, Olakunle Anthony: Management and coordination of responsibility for the research activity planning and execution. Bayode, Lawrence: Preparation, creation, and/or presentation of the published work by those from the original research group, specifically critical review, commentary, or revision – including pre- or post-publication stages. Anamu, Silas: Oversight and leadership responsibility for the research activity planning and execution, including mentorship external to the core team. Olorundaisi, Emmanuel: Literature reviews. Ayodele, Olusoji: Preparation, creation, and/or presentation of the published work by those from the original research group, specifically critical review, commentary, or revision – including pre- or post-publication stages. Mkhatshwa, Sindile: Microscopy analysis. Odetola, Peter: Literature reviews. Olubambi, Peter: Supervision and verification of facts about the review, whether as a part of the activity or separate, of the overall reproducibility of results other research outputs.

References

- A.O. Adegbenjo et al., Dependence of fracture patterns in spark plasma sintered irregular shaped Ti6Al4V powders on densification, Procedia Manuf. 7 (2017) 567–572 [CrossRef] [Google Scholar]

- V. Amigó et al., Microstructural evolution of Ti-6Al-4V during the sintering of microspheres of Ti for orthopedic implants, J. Mater. Process. Technol. 141 (2003) 117–122 [CrossRef] [Google Scholar]

- R. Balasubramanian et al., Development of nanostructured titanium implants for biomedical implants-a short review, Mater. Today: Proc. 46 (2021) 1195–1200 [CrossRef] [Google Scholar]

- Y. Cao et al., In situ synthesis of TiB/Ti6Al4V composites reinforced with nano TiB through SPS, Mater. Trans. 56 (2015) 259–263 [CrossRef] [Google Scholar]

- O.A. Ogunmefun et al., A critical review of dispersion strengthened titanium alloy fabricated through spark plasma sintering techniques, J. Alloys Comp. (2023) 170407 [CrossRef] [Google Scholar]

- J. Luan et al., Improved ductility and oxidation resistance of cast Ti-6Al-4V alloys by microalloying, J. Alloys Comp. 602 (2014) 235–240 [CrossRef] [Google Scholar]

- V. Vijay et al., Review of various surface treatment techniques on titanium alloys and their protective effects against corrosion, J. Surf. Sci. Technol. 23 (2007) 49 [Google Scholar]

- S.C. Tjong, Y.-W. Mai, Processing-structure-property aspects of particulate-and whisker-reinforced titanium matrix composites, Compos. Sci. Technol. 68 (2008) 583–601 [CrossRef] [Google Scholar]

- A. Lisiecki, J. Piwnik, Tribological characteristic of titanium alloy surface layers produced by diode laser gas nitriding, Arch. Metall. Mater. 61 (2016) 543–552 [CrossRef] [Google Scholar]

- G. Welsch, R. Boyer, E. Collings, Materials properties handbook: titanium alloys, ASM International, 1993 [Google Scholar]

- J. Chevalier et al., The tetragonal‐monoclinic transformation in zirconia: lessons learned and future trends, J. Am. Ceram. Soc. 92 (2009) 1901–1920 [CrossRef] [Google Scholar]

- A.K. Gain, L. Zhang, M.Z. Quadir, Composites matching the properties of human cortical bones: The design of porous titanium-zirconia (Ti-ZrO2) nanocomposites using polymethyl methacrylate powders, Mater. Sci. Eng.: A, 662 (2016) 258–267 [CrossRef] [Google Scholar]

- J.-H. Shin, S.-H. Hong, Fabrication and properties of reduced graphene oxide reinforced yttria-stabilized zirconia composite ceramics, J. Eur. Ceram. Soc. 34 (2014) 1297–1302 [CrossRef] [Google Scholar]

- A. Sayyadi-Shahraki et al., Densification and mechanical properties of spark plasma sintered Si3N4/ZrO2 nano-composites, J. Alloys Comp. 776 (2019) 798–806 [CrossRef] [Google Scholar]

- F. Lange, L. Falk, B. Davis, Structural ceramics based on Si3N4-ZrO2 (+ Y2O3) compositions, J. Mater. Res. 2 (1987) 66–76 [CrossRef] [Google Scholar]

- H. Attar et al., Nanoindentation and wear properties of Ti and Ti-TiB composite materials produced by selective laser melting, Mater. Sci. Eng.: A, 688 (2017) 20–26 [CrossRef] [Google Scholar]

- S. Ehtemam-Haghighi, G. Cao, L.-C. Zhang, Nanoindentation study of mechanical properties of Ti based alloys with Fe and Ta additions, J. Alloys Comp. 692 (2017) 892–897 [CrossRef] [Google Scholar]

- M.D. Hayat et al., Titanium metal matrix composites: an overview, Compos. Part A: Appl. Sci. Manuf. 121 (2019) 418–438 [CrossRef] [Google Scholar]

- S.O. Akinwamide et al., Characterization of pulse electric current sintered Ti-6Al-4V ternary composites: Role of YSZ-Si3N4 ceramics addition on structural modification and hydrogen desorption, Mater. Today Commun. 36 (2023) 106706 [CrossRef] [Google Scholar]

- F. Kgoete et al., Influence of Si3N4 on Ti-6Al-4V via spark plasma sintering: Microstructure, corrosion and thermal stability, J. Alloys Comp. 763 (2018) 322–328 [CrossRef] [Google Scholar]

- B.A. Obadele, O.O. Ige, P.A. Olubambi, Fabrication and characterization of titanium-nickel-zirconia matrix composites prepared by spark plasma sintering, J. Alloys Comp. 710 (2017) 825–830 [CrossRef] [Google Scholar]

- H. Yang et al., Reinforcement size dependence of load bearing capacity in ultrafine-grained metal matrix composites, Metall. Mater. Trans. A, 48 (2017) 4385–4392 [CrossRef] [Google Scholar]

- P. Maurya et al., Review on study of internal load transfer in metal matrix composites using diffraction techniques, Mater. Sci. Eng.: A, 840 (2022) 142973 [CrossRef] [Google Scholar]

- B.A. Obadele et al., Improving the tribocorrosion resistance of Ti6Al4V surface by laser surface cladding with TiNiZrO2 composite coating, Appl. Surf. Sci. 345 (2015) 99–108 [CrossRef] [Google Scholar]

- J. Rakotoniaina et al., Distribution and formation of silicon carbide and silicon nitride precipitates in block-cast multicrystalline silicon, in: Proceedings of the 20th European Photovoltaic Solar Energy Conference and Exhibition, Barcelona, Spain, 2005 [Google Scholar]

- A.M. Okoro et al., Nanoindentation studies of the mechanical behaviours of spark plasma sintered multiwall carbon nanotubes reinforced Ti6Al4V nanocomposites, Mater. Sci. Eng.: A, 765 (2019) 138320 [CrossRef] [Google Scholar]

- W.C. Oliver, G.M. Pharr, Measurement of hardness and elastic modulus by instrumented indentation: advances in understanding and refinements to methodology, J. Mater. Res. 19 (2004) 3–20 [CrossRef] [Google Scholar]

- A. Miklaszewski, D. Garbiec, K. Niespodziana, Sintering behavior and microstructure evolution in cp-titanium processed by spark plasma sintering, Adv. Powder Technol. 29 (2018) 50–57 [CrossRef] [Google Scholar]

- A. Babapoor et al., Effects of spark plasma sintering temperature on densification, hardness and thermal conductivity of titanium carbide, Ceram. Int. 44 (2018) 14541–14546 [CrossRef] [Google Scholar]

- S. Jeje et al., Effect of temperature on densification, microstructural evolution and mechanical properties of Ti-5Al-1Mo developed via spark plasma sintering, in: IOP Conference Series: Materials Science and Engineering, IOP Publishing, 2019 [Google Scholar]

- J.H. Park et al., Densification and mechanical properties of titanium diboride with silicon nitride as a sintering aid, J. Am. Ceram. Soc. 82 (1999) 3037–3042 [CrossRef] [Google Scholar]

- D.M. Jarząbek, The impact of weak interfacial bonding strength on mechanical properties of metal matrix-ceramic reinforced composites, Compos. Struct. 201 (2018) 352–362 [CrossRef] [Google Scholar]

- A.L. Rominiyi, P.M. Mashinini, Nanoindentation study of mechanical and wear properties of spark plasma sintered Ti-6Ni-xTiCN composites, Ceram. Int. 49 (2023) 2194–2203 [CrossRef] [Google Scholar]

- E. Shankar, S.B. Prabu, Microstructure and mechanical properties of Ti (C, N) based cermets reinforced with different ceramic particles processed by spark plasma sintering, Ceram. Int. 43 (2017) 10817–10823 [CrossRef] [Google Scholar]

- T. Sritharan, F. Boey, A. Srinivas, Synthesis of complex ceramics by mechanochemical activation, J. Mater. Process. Technol. 192 (2007) 255–258 [CrossRef] [Google Scholar]

- L. Dong et al., Interface engineering of graphene/copper matrix composites decorated with tungsten carbide for enhanced physico-mechanical properties, Carbon 173 (2021) 41–53 [CrossRef] [Google Scholar]

- O.E. Falodun et al., Effect of TiN and TiCN additions on spark plasma sintered Ti-6Al-4V, Part. Sci. Technol. 38 (2020) 156–165 [CrossRef] [Google Scholar]

- A. Teber et al., Effect of SPS process sintering on the microstructure and mechanical properties of nanocrystalline TiC for tools application, Int. J. Refract. Metals Hard Mater. 30 (2012) 64–70 [CrossRef] [Google Scholar]

- O.E. Falodun et al., Effect of sintering parameters on densification and microstructural evolution of nano-sized titanium nitride reinforced titanium alloys, J. Alloys Comp. 736 (2018) 202–210 [CrossRef] [Google Scholar]

- D. François et al., Elastoviscoplasticity, Mechanical Behaviour of Materials: Volume II: Viscoplasticity, Damage, Fracture and Contact Mechanics, 1998, p. 1–83 [Google Scholar]

- D. François, A. Pineau, A. Zaoui, Mechanical behaviour of materials, Springer, 1998, Vol. 1 [Google Scholar]

- A. Basak et al., Challenges and recent developments on nanoparticle-reinforced metal matrix composites, Fillers and Reinforcements for Advanced Nanocomposites, 2015, p. 349–367 [CrossRef] [Google Scholar]

- Y. Zhao et al., Microstructure and mechanical properties of Ti-C-TiN-reinforced Ni204-based laser-cladding composite coating, Ceram. Int. 47 (2021) 5918–5928 [CrossRef] [Google Scholar]

- M. Ostolaza et al., Influence of process parameters on the particle-matrix interaction of WC-Co metal matrix composites produced by laser-directed energy deposition, Mater. Des. 223 (2022) 111172 [CrossRef] [Google Scholar]

Cite this article as: Anthony Olakunle Ogunmefun, Olusoji Ayodele, Lawrence Bamidele Bayode, Ufoma Anamu, Emmanuel Olorundaisi, Sindile Mkhatshwa, Joseph Babalola, Michael Ngeleshi, Peter Odetola, Peter Apata Olubambi, Influence of sintering temperature on Ti6Al4V-Si3N4-ZrO2 ternary composites prepared by spark plasma sintering, Manufacturing Rev. 11, 5 (2024)

All Tables

Nano-mechanical readings for sintered composite, Ti6Al4V-5% Si3N4-4% ZrO2 at CT1-950, CT2-1100, and CT3-1200 °C.

All Figures

|

Fig. 1 A typical schematic diagram of SPS sintering. |

| In the text | |

|

Fig. 2 SEM micrographs of starting materials. (a) Ti-6Al-4V, (b) ZrO2, and (c) Si3N4. |

| In the text | |

|

Fig. 3 (a) SEM, EDS spectra, and elemental mapping of the SPSed composite CT1-950 °C, (b) Elemental mapping/EDS spectra of the SPSed composite CT2-1100 °C, (c) SEM, EDS spectra, and elemental mapping of the SPSed composite CT3-1200 °C. |

| In the text | |

|

Fig. 3 (Continued). |

| In the text | |

|

Fig. 4 X-ray diffractograms of SPSed Ti6Al4V-5%Si3N4-4%ZrO2 composites at temperatures 950 °C (CT1), 1100 °C (CT2), and 1200 °C (CT3). |

| In the text | |

|

Fig. 5 Relative density and porosity graph for sintered composites CT1, CT2, and CT3. |

| In the text | |

|

Fig. 6 Graphical representation of yield pressure & elastic strain of composites CT1, CT2, and CT3. |

| In the text | |

Current usage metrics show cumulative count of Article Views (full-text article views including HTML views, PDF and ePub downloads, according to the available data) and Abstracts Views on Vision4Press platform.

Data correspond to usage on the plateform after 2015. The current usage metrics is available 48-96 hours after online publication and is updated daily on week days.

Initial download of the metrics may take a while.